Fiberglass Columns

- TOP QUALITY MADE IN AMERICA

- LIMITED LIFETIME WARRANTY

- WATERPROOF & ROT RESISTANT

- CAP/BASE FROM SAME DURABLE MATERIAL AS SHAFT

- PAINT GRADE OR FACTORY COLORED AND TEXTURED

Fiberglass columns are made a variety of ways: Spun Cast Fiberglass, Cast Stone, Spray Cast Fiberglass and Pultruded Fiberglass. Royal Corinthian is our primary provider of cast products.

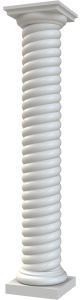

Spun Cast Fiberglass and Cast Stone

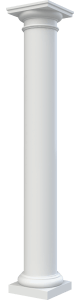

Generally, we quote thick wall, spun cast fiberglass columns. These have the highest load capacity and the wall thickness runs from ¼ – ½ inch thick. Spun Cast columns feel like stone and are very robust. Typically, calcium carbonate is the main filler used. As a filler, calcium carbonate allows cost reduction and improved mechanical properties. Calcium carbonate comes from sedimentary rocks (chalk, limestone), marbles and minerals (dolomite). These hollow fiberglass columns feel like stone and are extremely strong.

Cast stone columns are offered in 6 standard colors which fully permeate the column. Custom colors are also available. These columns are normally made in one uniform color; however, Royal Corinthian can mix in various aggregates to achieve a “dirtier” stone look. Most cast stone columns are lightly textured using a sandblasting method. Smooth finish and a coral finish, using actual coral aggregate, are also available.

Even though cast fiberglass columns are extremely robust, still they are considered lightweight. A round tapered 12 inch x 8 foot plain shaft weighs about 128 pounds. If your project requires lighter columns, Royal Corinthian can substitute lightweight filler which decreases the weight by approximately 25%, while maintaining the same material thickness.

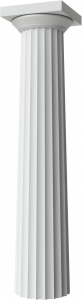

Spray Cast Fiberglass

Spray Cast columns are made like fiberglass boat hulls. They are thin, light, and strong. Spray cast columns are available in all sizes and configurations. Spray cast fiberglass columns cost less on larger size columns.

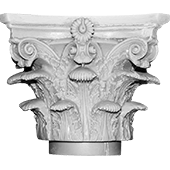

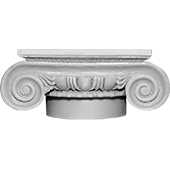

Caps and Bases

Many more decorative cap patterns are available.

Pultruded Fiberglass

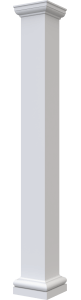

Pultrusion is a process where raw materials (in this case, glass fiber reinforcements and resins) are drawn into a profile die by a mechanical pulling force. These fibers are injected with resins while under tension, where they are combined and cured. The column wall thickness is about 1/8 inch. The primary advantages of pultruded columns are lower cost and lighter weight. Pultruded columns are available in non-tapered round and square columns in limited sizes.

CLASS A FIRE RATING OPTIONAL

When projects call for Class A fire-rated fiberglass columns, Alumina Trihydrate (ATH) is mixed in with the calcium carbonate to form filler that meets the ASTM E 84 Class A test method for surface flame spread and smoke density. Without ATH, the fiberglass columns will still pass the flame spread Class A test but fail the smoke test (which usually isn’t a concern for exterior use).